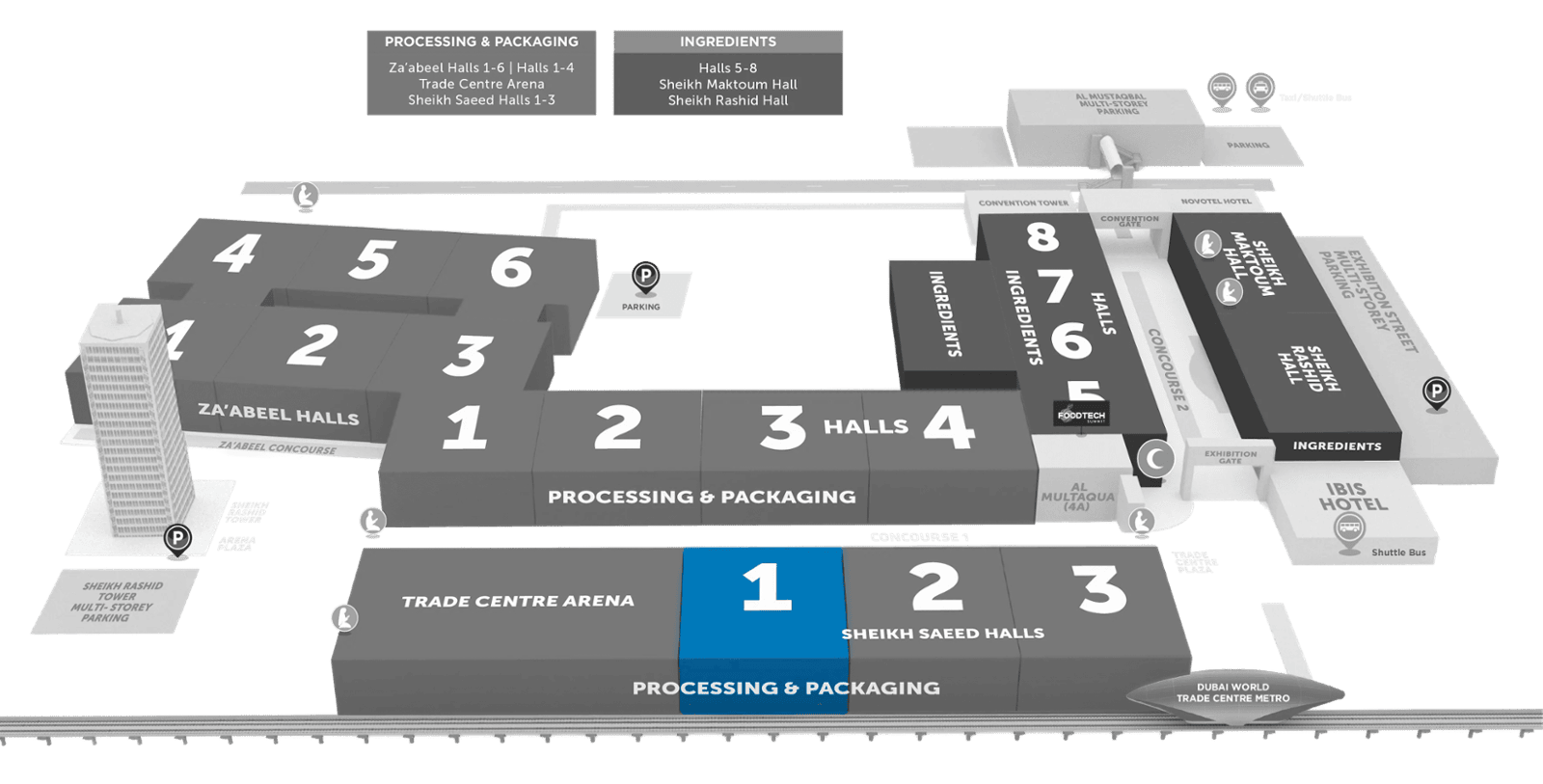

Find us at the German Pavilion!

📍Shk Saeed Hall 1, S1 - J3 (Dubai World Trade Centre)

📅 4 - 6 November

⏰10:00 AM - 06:00 PM

Who Do We Serve?

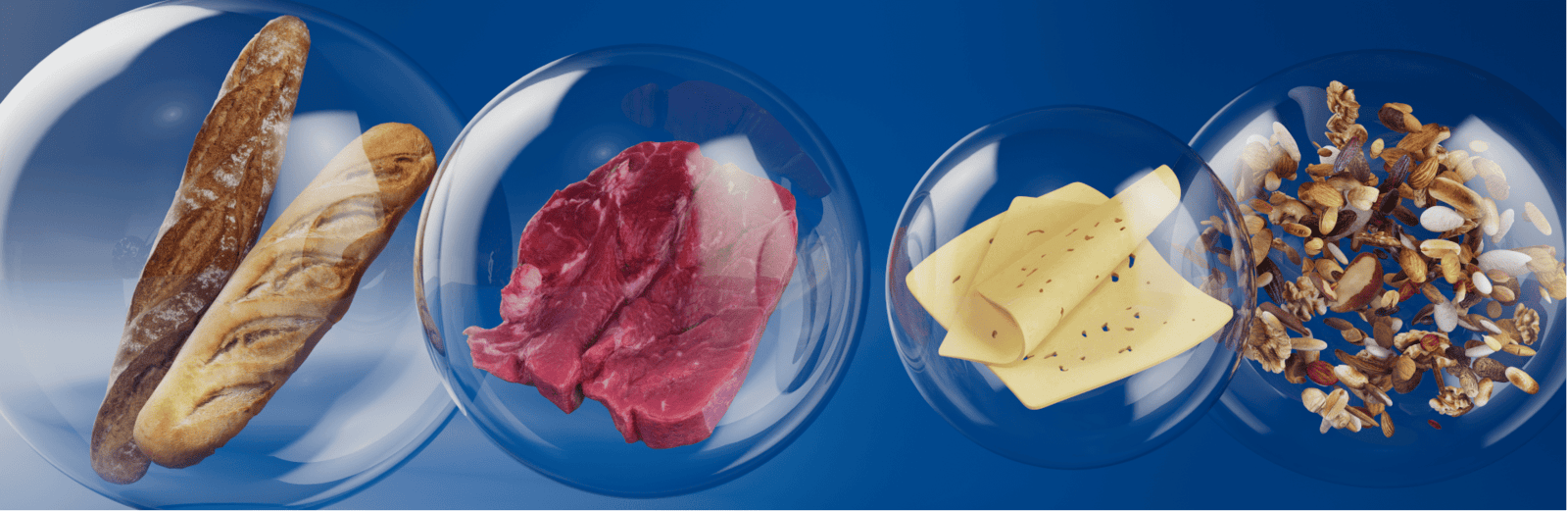

Industries That Depend on MAP Integrity

Meat, Poultry & Seafood

Guaranteeing color preservation and preventing spoilage through precise gas analysis and leak-proof seals.

Design

Fresh Produce

Maintaining the ideal atmosphere to slow respiration and extend the lifespan of delicate products.

Dairy & Bakery

Ensuring the integrity of sensitive products like cheese, milk powders, and artisan breads through validated packaging processes.

Coffee & Snacks

Providing the oxygen barrier required to keep products fresh and flavorful until the point of consumption.

Download your copy instantly and take control of your product quality!

Our comprehensive e-book, "Future Fresh:

A Manufacturer's Guide to Shelf-Life Extension," details the science, techniques, and, most importantly, the quality control measures needed for success.

Inside, you'll learn how to:

Select and verify the essential gas mixtures for various food types.

- Implement best practices for sealing and film testing.

Use modern gas analysis to meet global regulatory standards.